Trunnion Ball Valve

F51 High Temperature Duplex Stainless Steel Ball Valve

Features & Benefits

1. Structure : 2 pieces or 3 pieces body

2. High shut-off sealing mechanism and low torque operation

3. Block and bleed function

4. Self-cavity pressure relief

5. Fire safe design

6. Blow out proof stem construction

7. Anti-static design

8. Locking device (for lever handle operation)

9. ISO 5211 actuator mounting

10. Emergency grease injection (option)

11. PN design can be available

LNG Cryogenic Extended Stem Ball Valve

Features & Benefits

1. Low Operating Torque

2. Fireproof Structure Design

3. Anti-static Structure

4. Reliable seat sealing structure

5. Single Sealing (automatic Pressure Relief In Middle Cavity Of Valve)

LCB Low Temperature Gearbox Fire Safe Trunnion Ball Valve

Features & Benefits

1. Didtek Ball Valve can be quickly opened and closed with a quarter turn movement

2. Ensure a very tight seal without the need for high torque forces

3. have a compact design (this is the main difference between a ball valve and a gate valve – which are both on/off devices).

4. In a floating valve, the ball is suspended in the flowing fluid and is kept in position by the compression of two elastomeric seats against it.

5. Plant fires are a serious concern for soft-seated ball valves because of possible fluid leakage and consequent increase of the fire magnitude caused by deterioration of resilient sealing materials.

6. The “Full port” (FB) type features a bore size (the hole of the ball) matching the bore size of the connected piping. Full port ball valves minimize the pressure drop that is generated by reduced port valves but they are of course more bulky, heavy and expensive. FB ball valves are better suited, than RB ball valves, for throttling applications.

RTJ High-pressure Carbon Steel Ball Valve

Features & Benefits

1. Emergency Sealing Device

2. Safety Relief Device

3. Blow-out Proof Stem

4. Anti Static Design

5. Double Block And Bleed

6. Cavity Pressure Relief

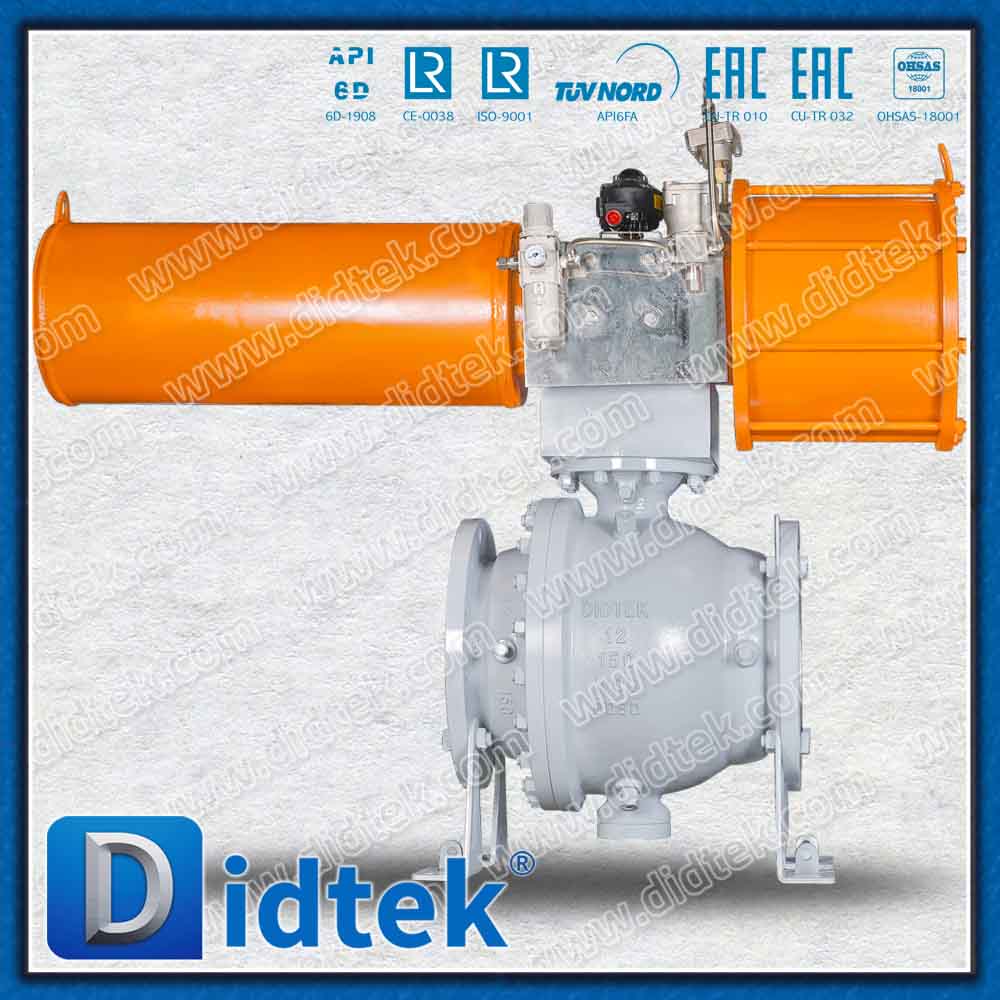

Pneumatic Actuator Low Torque Trunnion Ball Valve

Features & Benefits

1. Reliability and Durability

2. Fast Switching Speed

3. Convenient Automation Control

4. Fluid Control Capability

5. Zero Leakage Design

6. Wide Applicability

7. Easy Maintenance

09G2S Metal Seated Butt Welded Trunnion Ball Valves

Features & Benefits

1. Double Sealing (double Piston)

2. Safety Relief Device

3. The 2-piece flanged end floating ball valve from Kinvalve is available in stainless steel and carbon steel bodies.

4. Available in sizes form 1/2″ – 12″, they come with an ISO 5211 mounting pad for automatic actuation.

5. Meeting all Class requirements, this ball valve is relatively affordable and offers excellent versatility in application.

6. Didtek’s full-port design, flanged end 3-piece floating ball valves are ideal for the safest inline maintenance.

7. The valves come with a blowout-proof stem design.

4A Anti-explosion Duplex Pneumatic Ball Valve

Features & Benefits

1. Blow out proof stem construction

2. Anti-static design

3. Locking device (for lever handle operation)

4. ISO 5211 actuator mounting

5. Emergency grease injection (option)

6. PN design can be available

Double Block and Bleed Capabilities

Less Torque

No Size Limit

Spring-Loaded Seats

Customizable Features

Self Relief Pressure

Ease of Operation

What Are Trunnion Ball Valves?

The stem of a trunnion ball valve is rigidly attached to the ball, which prevents the ball from moving anywhere except on its axis. Since the ball does not “float” downstream with the pressure of the media, trunnion ball valves can maintain a proper seal on both sides simultaneously. This is especially crucial for multi port valves and valves in very low-pressure applications in which the flow of media is not strong enough to push the ball against its downstream seat.

How do Trunnion Ball Valves Work?

Trunnion ball valve manufacturer designs their trunnion ball valve to work in a way similar to a floating ball valve. The working principle of a trunnion ball valve involves rotating the ball to control fluid or gas flow.

How is a Trunnion Ball Valve Constructed?

The construction method of a trunnion ball valve used in different industrial valve companies involves the assembly of several components, with specific materials are chosen for their properties and suitability for the valve’s intended application.