Size Range

1/2"~8"

Temperature Range

-196℃~650℃

Pressure Rating

ASME CL, 150, 300, 600

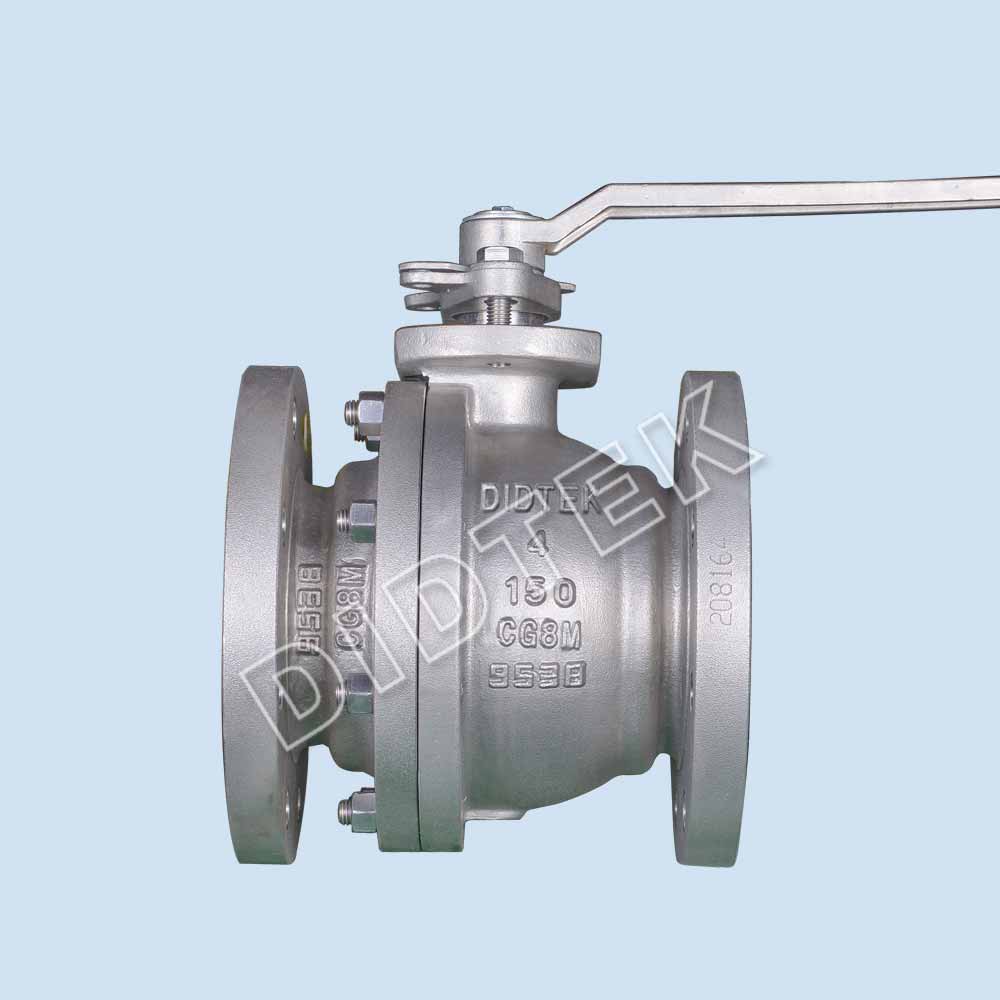

1. Didtek Ball Valve Stem head design provides mounting of the lever handle always in parallel to the flow passage. Misalignment of the handle is thus prevented.

2. The lower end of the stem is designed with an integral collar to be blowout-proof. It also functions as the backseat for assured stem sealing.

3. An antistatic feature is provided to ensure electrical continuity between ball, stem, and body.

4. Facility for mounting a locking device for prevention of accidental valve operation is provided.

5. Plant fires are a serious concern for soft-seated ball valves because of possible fluid leakage and consequent increase of the fire magnitude caused by deterioration of resilient sealing materials.

6. Didtek ball valves are engineered for fires safety and successfully fire tested to minimize both external and internal fluid leakage after plant fires.

Didtek Cast Floating Soft Seat Ball Valve are ideal where chemical compliance is required. They are made of thermoplastic material and not recommended for abrasive, dirty liquids as they can break down easily. They work best in medium pressures and temperatures below 260°C.

1/2'' to 8''

CG8M

-196 to 650°C

Monel

ASME CL150, 300, 600

PEEK

Zero Leakage

ASTM B148 C63200

Two Piece

API 6D

Flanged

API 598

Lioyd's CE, Lioyd's UKCA, EAC, ISO 9001, API 6D, API 6FA

Full

ASME B16.10

Oil and Gas Pipeline, Offshore Platforms, Onshore Terminals, Emergency Shutdown, Suction and Discharge Isolation, Block and Bypass, Pumping, Compression and Reinjection Units, Metering Stations, Pig Traps, Surge-Relief Skids, Decoking Isolation, Buried Services, Produced Water (Brine) Services