Size Range

2"~48"

Temperature Range

-29℃~425℃

Pressure Rating

ASME CL, 150, 300

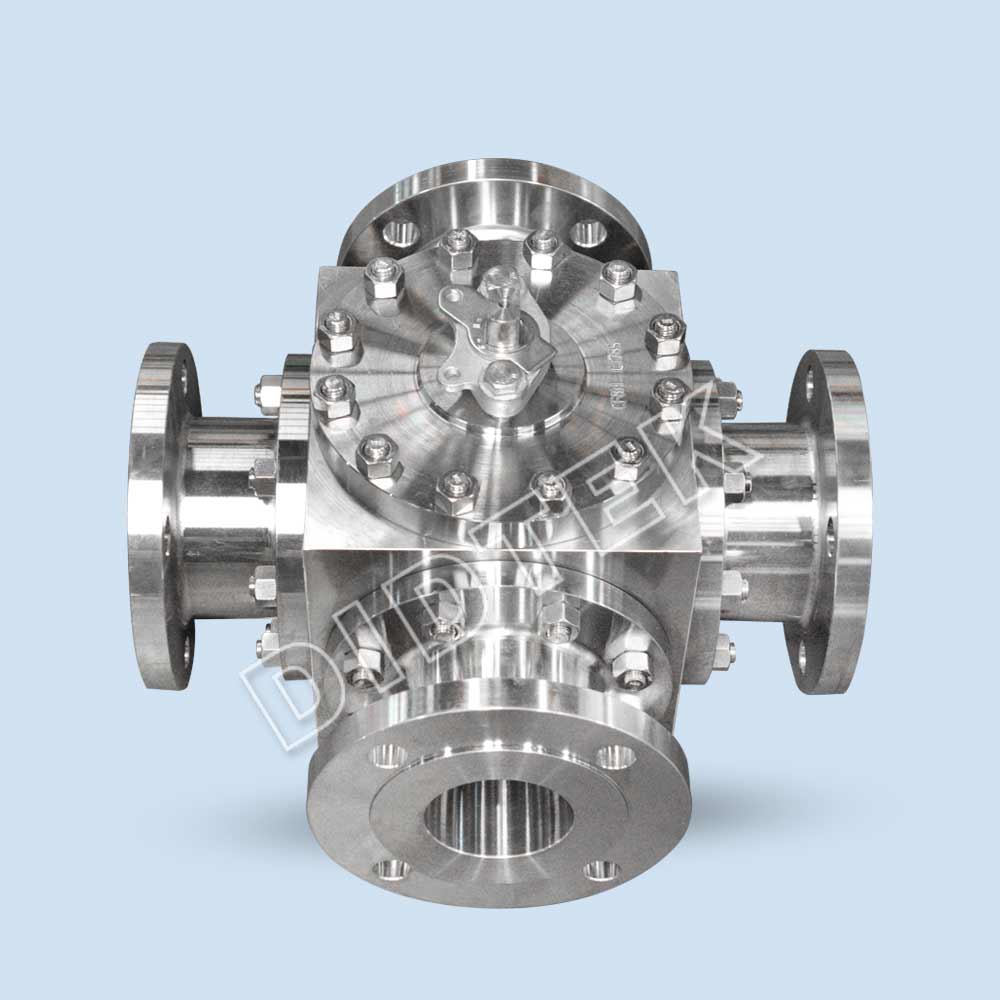

1. Double-L Port Configuration

2. Live-Loaded Stem Packing

Provides constant load on the stem seal and extends service life

3. Blow-Out-Proof Stem

Stem is bottom loaded to prevent removal when valve is in service

4. Balanced 4-Seat Construction

4 seats maintain positive ball alignment

5. Reduced Number of Valves Required in Piping System

6. Invenstment Cast Body and End Caps

Didtek 4 Way Ball Valves, The utilization of common bolted on ends and four seated design offers the ability to interchange port configurations and allow every port to be an inlet and/or a blocked flow port. This offers tremendous flexibility, a multitude of flow path options and the ability to use various end connections on each port.

2'' to 48''

CF8M

-29 to 425°C

ASTM A479 Type 410

17-4PH

XM-19

ASTM A182 F316

ASME CL150, 300

RPTFE, Nylon, Devlon, PEEK, Tek-Fil, TFM

Zero Leakage

ASTM A105 w/ENP

ASTM A350 Gr. LF2 w/ENP

ASTM A182 Gr. F316

ASTM A182 Gr. F316 w/ENP

API 6D, BS5351, ASME B16.34

Flanged

API6D, API608, ASME B16.34

Lioyd's CE, Lioyd's UKCA, EAC, ISO 9001, API 6D, API 6FA

Full

ASME B16.10, API 6D

Oil and Gas Pipeline, Offshore Platforms, Onshore Terminals, Emergency Shutdown, Suction and Discharge Isolation, Block and Bypass, Pumping, Compression and Reinjection Units, Metering Stations, Pig Traps, Surge-Relief Skids, Decoking Isolation, Buried Services, Produced Water (Brine) Services